Lots of vehicles, lots of tires: this is how commercial fleets could be described. It is a fact that the silver medal on a hypothetical podium of the major fleet expenses goes to fuel costs (the gold medal goes to salaries), which are notoriously linked to tire pressure. From this simple fact, it is clear that timely tire pressure plays a vital role in containing costs. Only some time ago, this operation would have been carried out in a fleet’s workshop or by the individual driver during his journey. This method was obviously cumbersome, un-plannable and inefficient. Technology has fortunately evolved, and today it is possible to have an effective remote monitoring system. In addition, automatic tire inflation has also become more widely available in recent years.

Significant number

The North American Council for Freight Efficiency in 2020 updated one of its earlier reports on the benefits of pressure restoration systems on freight trucks. The report is part of an effort by NACFE to give companies insights into technologies aimed at improving freight efficiency. What emerged was that despite the known benefits of correct tire pressures, 3 percent of trailers and nearly 3.5 percent of trucks were found with four or more tires underinflated by 20 psi (1.4 bar). NACFE estimates that a drop of only 10 psi translates into 0.5% to 1% higher fuel consumption. Another interesting fact is that 25% to 30% of trucks and about 15% of trailers have tire pressure monitoring systems. Despite this fact, at least 1 in 5 vehicles are operating with one or more tires underinflated by 20 psi or more, which makes the case for combining pressure monitoring systems with an active pressure management.

The North American Council for Freight Efficiency in 2020 updated one of its earlier reports on the benefits of pressure restoration systems on freight trucks. The report is part of an effort by NACFE to give companies insights into technologies aimed at improving freight efficiency. What emerged was that despite the known benefits of correct tire pressures, 3 percent of trailers and nearly 3.5 percent of trucks were found with four or more tires underinflated by 20 psi (1.4 bar). NACFE estimates that a drop of only 10 psi translates into 0.5% to 1% higher fuel consumption. Another interesting fact is that 25% to 30% of trucks and about 15% of trailers have tire pressure monitoring systems. Despite this fact, at least 1 in 5 vehicles are operating with one or more tires underinflated by 20 psi or more, which makes the case for combining pressure monitoring systems with an active pressure management.

Controlling or managing tire pressure?

NACFE highlights the advantages from using Automatic Tire Inflation Systems (ATIS) far outweigh the disadvantages. Among the advantages is a 1.5% improvement in fuel consumption, which leads to recouping the investment in just one year. It also improves tire lifespan as operating with pressures below the correct levels wears tires down prematurely. Properly inflated tires are also less likely to blowout, increasing safety and minimizing downtime. ATIS systems ensure a balanced pressure in dual tire assemblies. ATIS devices are generally not connected to a remote-control system, rather the trend is for them to be increasingly integrated into telematics remote management platforms.

NACFE highlights the advantages from using Automatic Tire Inflation Systems (ATIS) far outweigh the disadvantages. Among the advantages is a 1.5% improvement in fuel consumption, which leads to recouping the investment in just one year. It also improves tire lifespan as operating with pressures below the correct levels wears tires down prematurely. Properly inflated tires are also less likely to blowout, increasing safety and minimizing downtime. ATIS systems ensure a balanced pressure in dual tire assemblies. ATIS devices are generally not connected to a remote-control system, rather the trend is for them to be increasingly integrated into telematics remote management platforms.

“Reading” tire pressure data from a distance

The benefits of remote tire pressure control, possibly integrated with an automatic inflation system, is beyond question. A centralized remote management system can prove an aid in improving the effectiveness of TPMS pressure sensors. Indeed, truck drivers are already busy driving and cannot waste time and energy in monitoring tire pressure trends, so they are likely to think about tires only if an alarm signal is triggered. Remote monitoring from a control room, on the other hand, is more likely to detect not only pressure loss but also other issues. Pressure fluctuations are always possible, for example due to altitude, outside temperature or changing weights. However, a slow but steady loss of pressure is potentially dangerous because it will lead to underinflation and overheating, which can lead to serious damage. A telematic monitoring system can distinguish between the need for immediate action or plan an intervention when the driver reaches his destination.

Remote control can extract sophisticated data

Advanced telematics systems can detect specific information from tire pressure data, such as how long the tire has been working at less-than-optimal pressure. If the period has been too long, then a warning is issued to replace the tire in question. A careful analysis of the pressure data and its trend makes it possible to determine, for example, a problem with the brakes of a trailer. If the pressure systematically rises when the vehicle moves and drops when it stops, could mean that a brake had an imperfect "return" of the friction material, which then overheats when moving - and with it the wheel and tire - due to constant friction. Crossing the pressure and temperature information with the positioning information further expands the information that can be acquired. The same can be said if the anomalies are often found in the same tire: the problem could be in the rim or in the axle more than in the tire itself. If problems seem to occur in the same locations, it may mean that something is wrong, for example, in the company’s yard riddles with debris, nails and elements capable of puncturing the tires. As the alerts are more specific and targeted, systems of this type send fewer warnings to the driver, who will then pay more attention to them.

Fleet-friendly solutions

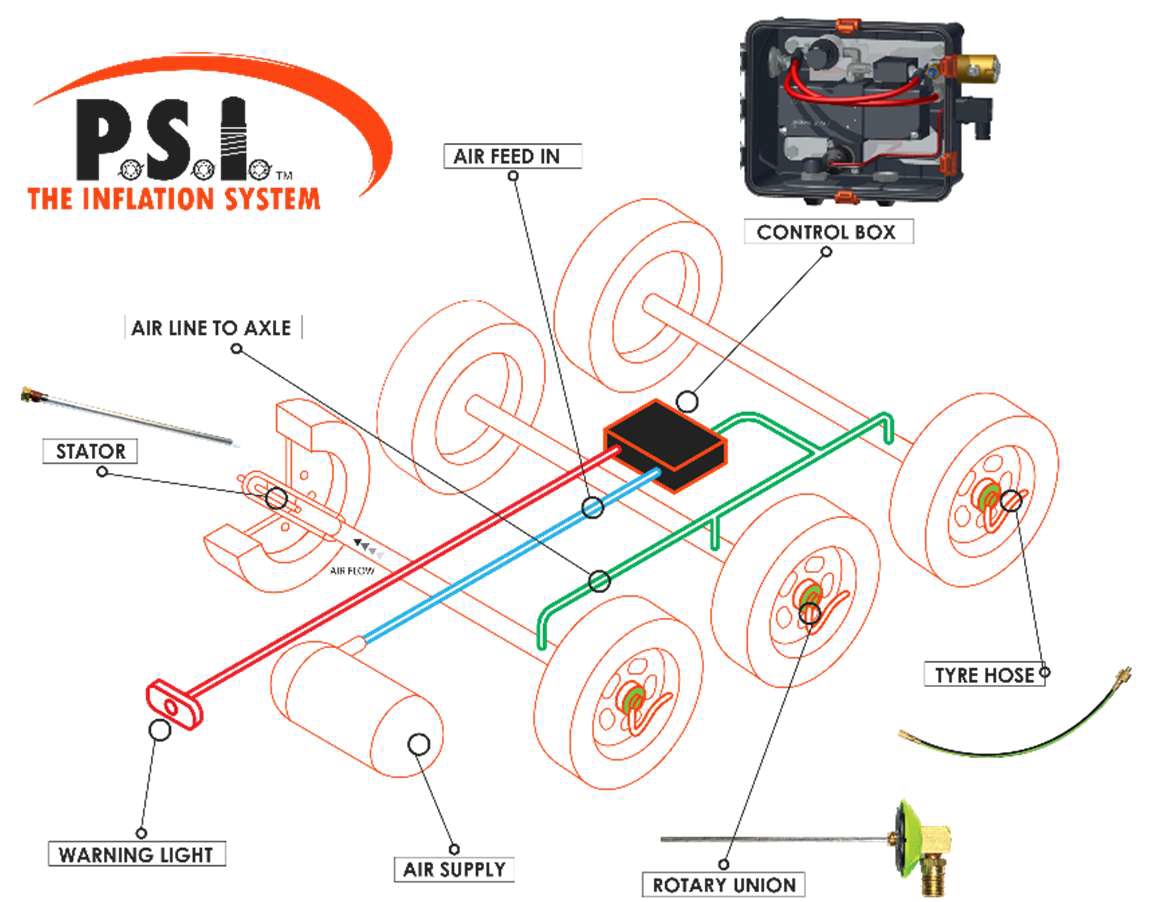

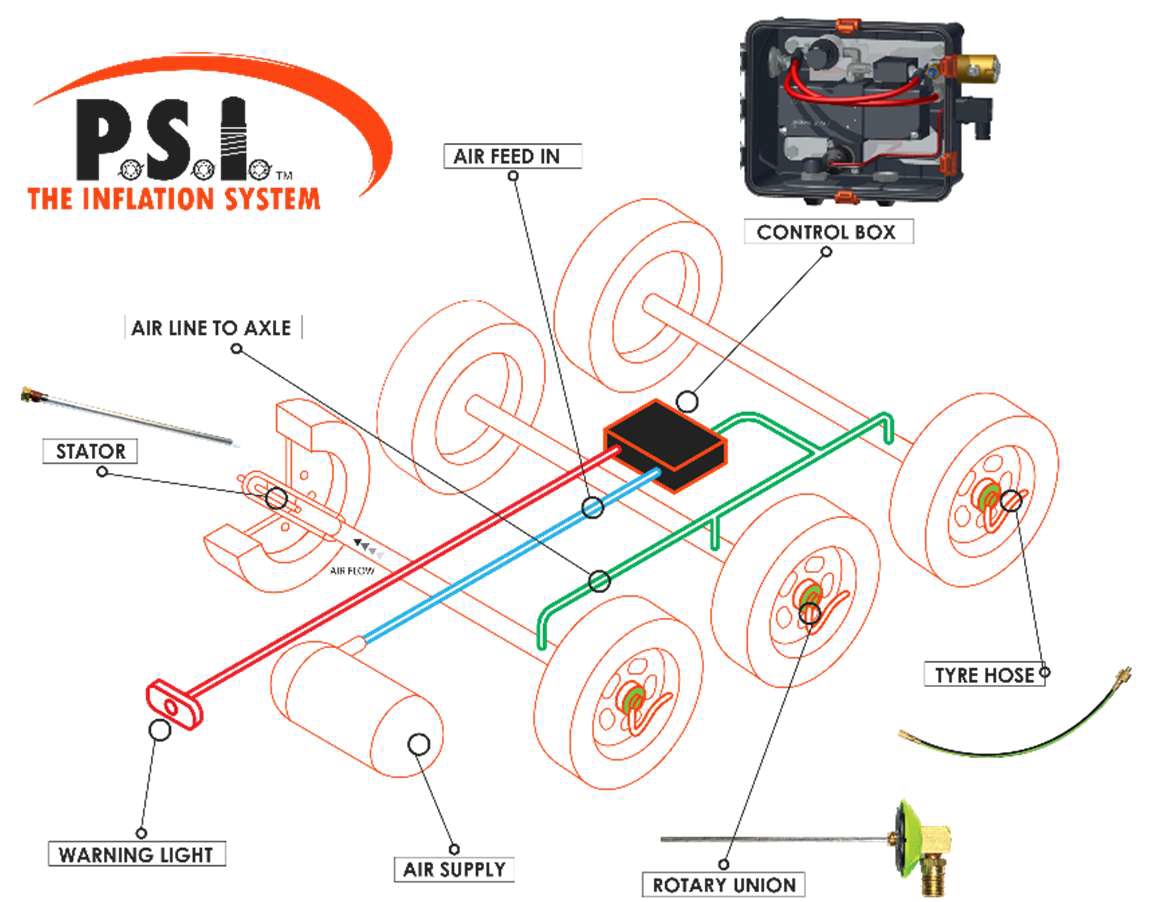

Fleet managers, as well as "owner-operators", now have a wealth of advanced solutions available for remote tire control. One of these dedicated to automatic tire inflation is the Vigia ATIS, which uses compressed air from the on-board system, conveyed through the axles and then to the hub (thanks to a rotating seal) and from there to the valves, to restore the correct pressure. The system can also be interfaced with the Gestya telematics platform that manages GPS and diagnostic data, including tire data, to enable remote control. Similar solutions are offered, for example, by SAF, P.S.I., Hendrickson, Meritor (also with an overheating alarm) and STAS. A special mention for Aperia's Halo, an ATIS that promises ease of assembly because it does not require hoses running through the hub and axles. Compressed air is in fact generated inside the device, mounted on the hub, thanks to a system that exploits the rotation of the wheel. The Connect version also enables telematic pressure monitoring with the advantages described above. Scores of telematic monitoring solutions are provided by tire manufacturers. Pirelli Cyberfleet, for example, includes sensors in the tires (of any type and brand as long as they are tubeless) that detect the working parameters and send them to an app for smartphones/tablets. The data is displayed in the device and then sent via a cloud for remote monitoring. Similar solutions are offered by Continental with its ContiPressureCheck system (also in the Live version for remote monitoring), Michelin with its MEMS 4 and Goodyear with its TPMS connected, via router, to a cloud. There are also proposals from other brands, such as ZF and its Wabco OptiTire, proposed in collaboration with Maxion Wheels. Axle and transmission manufacturer Dana has its own system, the cloud-based Rhombus TireAnalytics that can remotely control tire parameters.

The North American Council for Freight Efficiency in 2020 updated one of its earlier reports on the benefits of pressure restoration systems on freight trucks. The report is part of an effort by NACFE to give companies insights into technologies aimed at improving freight efficiency. What emerged was that despite the known benefits of correct tire pressures, 3 percent of trailers and nearly 3.5 percent of trucks were found with four or more tires underinflated by 20 psi (1.4 bar). NACFE estimates that a drop of only 10 psi translates into 0.5% to 1% higher fuel consumption. Another interesting fact is that 25% to 30% of trucks and about 15% of trailers have tire pressure monitoring systems. Despite this fact, at least 1 in 5 vehicles are operating with one or more tires underinflated by 20 psi or more, which makes the case for combining pressure monitoring systems with an active pressure management.

The North American Council for Freight Efficiency in 2020 updated one of its earlier reports on the benefits of pressure restoration systems on freight trucks. The report is part of an effort by NACFE to give companies insights into technologies aimed at improving freight efficiency. What emerged was that despite the known benefits of correct tire pressures, 3 percent of trailers and nearly 3.5 percent of trucks were found with four or more tires underinflated by 20 psi (1.4 bar). NACFE estimates that a drop of only 10 psi translates into 0.5% to 1% higher fuel consumption. Another interesting fact is that 25% to 30% of trucks and about 15% of trailers have tire pressure monitoring systems. Despite this fact, at least 1 in 5 vehicles are operating with one or more tires underinflated by 20 psi or more, which makes the case for combining pressure monitoring systems with an active pressure management.