There is so much information nowadays that we often speak of “data lakes”. However, collecting a lot of data is not enough: these must be processed in order to extract the information content they carry. The importance of data is now an established fact in all industrial sectors and beyond: one only must think of healthcare and public administration to realise this. A manufacturing sector as globally important as the rubber industry certainly cannot shy away from this trend, sticking to it in an innovative and creative manner.

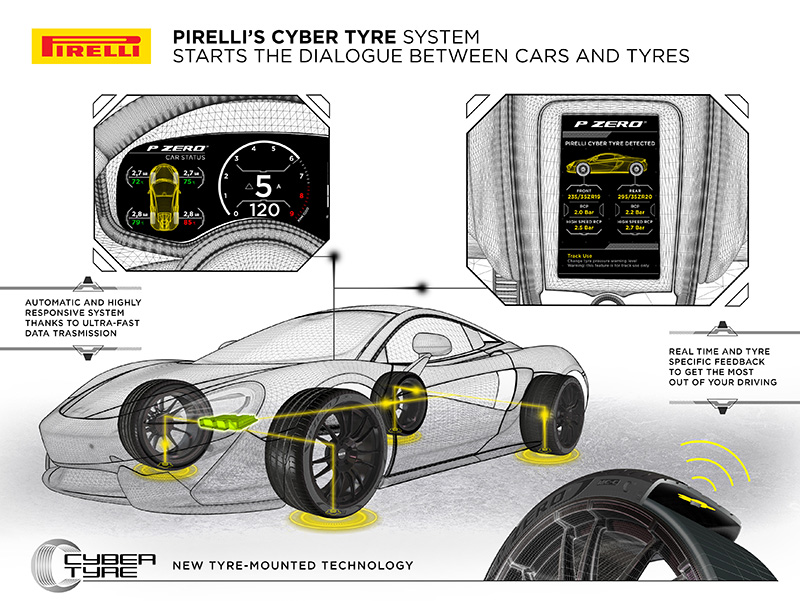

Pirelli and hi-tech production plants A concrete example of the application of these modern methods can be seen at Pirelli’s production facility in Silao, Mexico. At the end of 2022, the company declared further investments in the region of 114 million euro to increase High Value production at the site: the investment will increase annual production capacity by more than one million units, reaching 8.5 million tyres by 2025 from 7.2 million at the end of 2022. The Mexican factory has always produced tyres using Pirelli’s most recent solutions, such as Pirelli Noise Cancelling System, Cyber tyre sensors and Rfid data transmission: the latter solutions are aimed at tracking tyres to provide information on the logistics chain and tyre operating conditions. The huge investments in the Mexican plant have also served to implement Industry 4.0 principles, very much linked to connectivity and data generation/transmission/processing.

A concrete example of the application of these modern methods can be seen at Pirelli’s production facility in Silao, Mexico. At the end of 2022, the company declared further investments in the region of 114 million euro to increase High Value production at the site: the investment will increase annual production capacity by more than one million units, reaching 8.5 million tyres by 2025 from 7.2 million at the end of 2022. The Mexican factory has always produced tyres using Pirelli’s most recent solutions, such as Pirelli Noise Cancelling System, Cyber tyre sensors and Rfid data transmission: the latter solutions are aimed at tracking tyres to provide information on the logistics chain and tyre operating conditions. The huge investments in the Mexican plant have also served to implement Industry 4.0 principles, very much linked to connectivity and data generation/transmission/processing.

Measuring tyres during races Kistler is a pioneer in the field of dynamic measurements and collaborates with universities, motorsport teams and automotive OEMs to support innovative technologies, including autonomous driving. As motorsports is an excellent test bed for vehicle development, Kistler sensors are used by several teams. One of these is the Forze Hydrogen Racing Team from the Delft University of Technology, which uses Kistler sensors to measure tyre pressures, temperatures, torques and the dynamics on its single-seater Forze IX hydrogen car. In March 2023, at the Tire Technology Expo in Hannover, Kistler presented its new RoaDyn Racing, a wireless wheel force detector fitted to the rim to measure the forces to which the wheels, in particular the tyres, are subjected when moving. This information relates not only to traction but also to tyre wear, enabling manufacturers and racing teams to analyse and optimise tyre performance according to tracks, vehicle dynamics, weather conditions and other factors. This important data can be used to evaluate performance in short term motorsport application, as well as shifting the focus on longevity and reliability in the medium to long term as required in production vehicles. Either way, the volume of data generated is huge and this is where Kistler's new jBEAM Durability software comes in, a specific edition of the well-known jBEAM analysis and visualisation platform application. The application was developed in collaboration with Oem Automotive and promises flexibility, speed and efficiency in the data analysis and reporting required to get the best out of the signals generated by these advanced sensors.

Kistler is a pioneer in the field of dynamic measurements and collaborates with universities, motorsport teams and automotive OEMs to support innovative technologies, including autonomous driving. As motorsports is an excellent test bed for vehicle development, Kistler sensors are used by several teams. One of these is the Forze Hydrogen Racing Team from the Delft University of Technology, which uses Kistler sensors to measure tyre pressures, temperatures, torques and the dynamics on its single-seater Forze IX hydrogen car. In March 2023, at the Tire Technology Expo in Hannover, Kistler presented its new RoaDyn Racing, a wireless wheel force detector fitted to the rim to measure the forces to which the wheels, in particular the tyres, are subjected when moving. This information relates not only to traction but also to tyre wear, enabling manufacturers and racing teams to analyse and optimise tyre performance according to tracks, vehicle dynamics, weather conditions and other factors. This important data can be used to evaluate performance in short term motorsport application, as well as shifting the focus on longevity and reliability in the medium to long term as required in production vehicles. Either way, the volume of data generated is huge and this is where Kistler's new jBEAM Durability software comes in, a specific edition of the well-known jBEAM analysis and visualisation platform application. The application was developed in collaboration with Oem Automotive and promises flexibility, speed and efficiency in the data analysis and reporting required to get the best out of the signals generated by these advanced sensors.

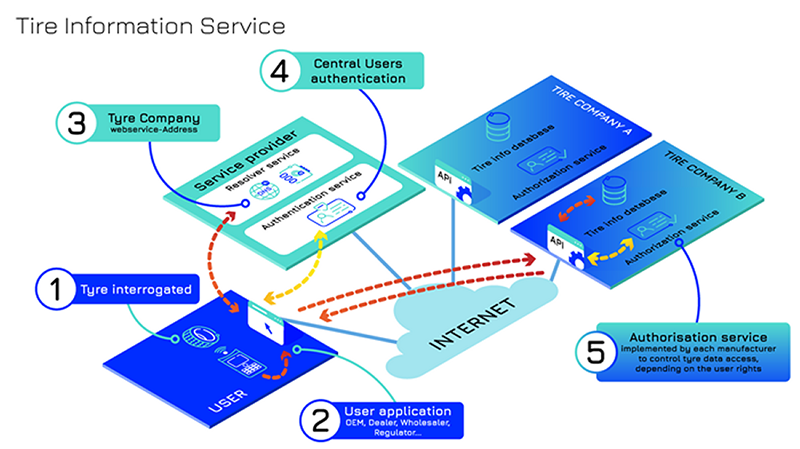

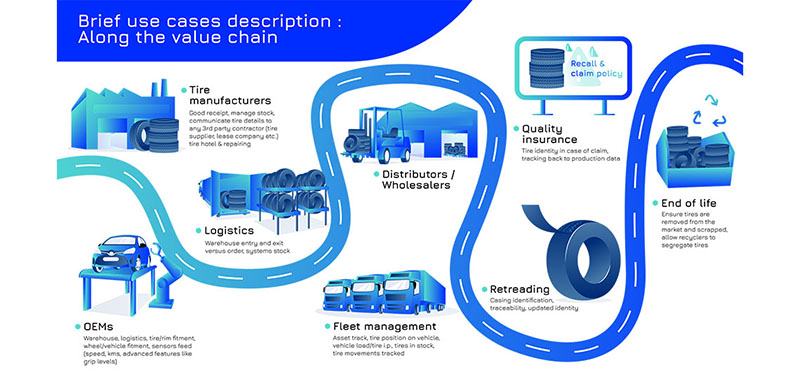

On the hunt for (standard) data The importance of data for the rubber and tyre industry led to the creation of the Global Data Service Organisation for Tyres and Automotive Components (Gdso) in early 2022. The association, whose founders include Bridgestone, Continental, Goodyear, Michelin and Pirelli, has grown rapidly, thanks also on the membership of bodies such as Etrto, Jatma, Tra and the US and Canadian trade associations. It is worth mentioning that Autopromotec 2022 hosted a round table to understand and see how the Tire Information Service works and its use cases already in development. In July 2022 Giti Tire joined the organisation and so did Sumitomo Rubber Industries in January this year. Therefore, also the Japanese group will now benefit from individual tyre identification and management systems for collecting, moving, processing and exchanging data in a standardised manner. An important achievement by the Gdso was the creation of the Tire Information Service (Tis), a platform that enables the transfer of tyre data through a unique product identifier. The organisation pays particular attention to privacy and IT security, a necessary precaution given that data is shared via the Web and Cloud. Within this framework Sumitomo will build a database to allow users to access its tyre data via Rfid technology. This ID protocol will improve industry traceability and quality control, improve responses to customer queries/complaints and combat the scourge of counterfeit tyres. Other effects of these technologies could be increased operational efficiency and safety by simplifying inventory management, making it easier to check when and where tyres were manufactured, installed and maintained.

The importance of data for the rubber and tyre industry led to the creation of the Global Data Service Organisation for Tyres and Automotive Components (Gdso) in early 2022. The association, whose founders include Bridgestone, Continental, Goodyear, Michelin and Pirelli, has grown rapidly, thanks also on the membership of bodies such as Etrto, Jatma, Tra and the US and Canadian trade associations. It is worth mentioning that Autopromotec 2022 hosted a round table to understand and see how the Tire Information Service works and its use cases already in development. In July 2022 Giti Tire joined the organisation and so did Sumitomo Rubber Industries in January this year. Therefore, also the Japanese group will now benefit from individual tyre identification and management systems for collecting, moving, processing and exchanging data in a standardised manner. An important achievement by the Gdso was the creation of the Tire Information Service (Tis), a platform that enables the transfer of tyre data through a unique product identifier. The organisation pays particular attention to privacy and IT security, a necessary precaution given that data is shared via the Web and Cloud. Within this framework Sumitomo will build a database to allow users to access its tyre data via Rfid technology. This ID protocol will improve industry traceability and quality control, improve responses to customer queries/complaints and combat the scourge of counterfeit tyres. Other effects of these technologies could be increased operational efficiency and safety by simplifying inventory management, making it easier to check when and where tyres were manufactured, installed and maintained.

Manufacturers are investing in big data and AI "Data is the new oil": this rather catchy phrase carries important implications, and it is not surprising that Bridgestone's Data Solutions initiative, was specifically created to unlock the potential of data. Using data science capabilities such as machine learning and Artificial Intelligence, anonymised raw data from both Bridgestone's and Webfleet's connected assets (we're talking about 2.5 billion km travelled by connected vehicles every month) and third-party sources are analysed to provide customised solutions to mobility providers. Customers will then be able to take advantage of the new opportunities arising from a connected world to improve road safety, business operations, traffic management, predictive maintenance and sustainability policies. In addition to sophisticated fleet management services, also obtained through the vehicle's CAN-Bus, Bridgestone Data Solutions is able to detect road surface damage, collect information on road signs and assess road conditions in different areas and thus determine which section is in need of repair. Not to be outdone, Michelin has likewise implemented activities to collect and process Big Data generated by vehicles fitted with its tyres. Its DDi - Driving Data to Intelligence - services are at the heart of the transformation strategy of one of the world’s leaders in mobility. There is no shortage of driving data, as several tens of millions of connected drivers in Europe and the United States make it possible to analyse more than 1.5 billion kilometres of roads travelled. The group intends to use its expertise in analysing driving behaviour to put it at the service of road safety, helping to take action before accidents occur. Next up, Goodyear, which has teamed up with Gatik to transport goods with self-driving vehicles. Their demonstrator truck uses Goodyear's SightLine technology to estimate tyre-to-road grip. This technology measures the wear, load, inflation pressure and temperature of the tyre and this data, combined in real time (thanks to AI) with weather data and compound friction patterns, allows them to estimate the grip of that tyre on that specific road. This information is shared via the cloud to Gatik's autonomous fleet, which then uses it to improve safety in the harsh conditions of Canada's ice-cold roads.

"Data is the new oil": this rather catchy phrase carries important implications, and it is not surprising that Bridgestone's Data Solutions initiative, was specifically created to unlock the potential of data. Using data science capabilities such as machine learning and Artificial Intelligence, anonymised raw data from both Bridgestone's and Webfleet's connected assets (we're talking about 2.5 billion km travelled by connected vehicles every month) and third-party sources are analysed to provide customised solutions to mobility providers. Customers will then be able to take advantage of the new opportunities arising from a connected world to improve road safety, business operations, traffic management, predictive maintenance and sustainability policies. In addition to sophisticated fleet management services, also obtained through the vehicle's CAN-Bus, Bridgestone Data Solutions is able to detect road surface damage, collect information on road signs and assess road conditions in different areas and thus determine which section is in need of repair. Not to be outdone, Michelin has likewise implemented activities to collect and process Big Data generated by vehicles fitted with its tyres. Its DDi - Driving Data to Intelligence - services are at the heart of the transformation strategy of one of the world’s leaders in mobility. There is no shortage of driving data, as several tens of millions of connected drivers in Europe and the United States make it possible to analyse more than 1.5 billion kilometres of roads travelled. The group intends to use its expertise in analysing driving behaviour to put it at the service of road safety, helping to take action before accidents occur. Next up, Goodyear, which has teamed up with Gatik to transport goods with self-driving vehicles. Their demonstrator truck uses Goodyear's SightLine technology to estimate tyre-to-road grip. This technology measures the wear, load, inflation pressure and temperature of the tyre and this data, combined in real time (thanks to AI) with weather data and compound friction patterns, allows them to estimate the grip of that tyre on that specific road. This information is shared via the cloud to Gatik's autonomous fleet, which then uses it to improve safety in the harsh conditions of Canada's ice-cold roads.

Siemens and Continental support smart factories Continental's push towards digitisation and the use of Big Data is expressed not only by being one of the founders of Gdso but also by the agreement signed with Siemens to supply automation systems and technologies for its production facilities. Its factories will therefore have Simatic controllers, WinCC Unified operator control units and industrial PCs as well as dedicated Siemens training for some Continental employees. Siemens will also provide Tyre Library, a software library for standardised control of sensors and actuators. This will simplify maintenance procedures in Continental's plants and also make the job easier for the suppliers of tools and equipment. Standardisation also allows machines to function in the same way, whatever their manufacturer, and this agreement increases Continental's sustainability because Siemens hardware, thanks to digital technologies, can enjoy extended life cycles.

Continental's push towards digitisation and the use of Big Data is expressed not only by being one of the founders of Gdso but also by the agreement signed with Siemens to supply automation systems and technologies for its production facilities. Its factories will therefore have Simatic controllers, WinCC Unified operator control units and industrial PCs as well as dedicated Siemens training for some Continental employees. Siemens will also provide Tyre Library, a software library for standardised control of sensors and actuators. This will simplify maintenance procedures in Continental's plants and also make the job easier for the suppliers of tools and equipment. Standardisation also allows machines to function in the same way, whatever their manufacturer, and this agreement increases Continental's sustainability because Siemens hardware, thanks to digital technologies, can enjoy extended life cycles.

Hankook teams up with Amazon Web Services for Artificial Intelligence

Artificial Intelligence could not fail to enter the tyre industry among others, and an interesting example of this synergy is the agreement that Hankook and Hankook Tire & Technology have signed with Amazon Web Services (Aws). The agreement concerns the development of an integrated Artificial Intelligence platform which involves also Snowflake, a cloud-based Software-as-a-Service that efficiently stores, processes and analyses large volumes of data. The aim of the collaboration is the creation of a cloud-based data analysis infrastructure that enables the creation of an integrated analysis 'environment' capable of using advanced AI and Machine Learning technologies. Aws' data lake and analysis infrastructure will be used while Snowflake will store the data to enable its migration to the cloud and digital transformation. This will create the perfect environment to collect and integrate Hankook Tire's internal data, to be used in research & development, production and quality departments. The platform will also collect external data, such as mobility data as well as info collected by Customer Service and integrate this huge amount of information for use by the company. Hankook will thus have a flexible tool that will improve tyre performance and quality, analyse performance data and also integrate customer feedback on iON tyres for electric vehicles. Thus, Hankook aims to improve the efficiency of new product development while addressing the issue of production quality.

Sensors, Ai and Big data the new frontier for the tyre business

Nicodemo Angì 04 luglio 2023

TOPICS

TAG

technical analysis | car | tires | truck | interview | automotive | tire dealer | road transport | motorcycle | Ford

MAGAZINE

FLIP MAGAZINE PAGES