Double trouble: chip crunch and very little is being done on “green policies”

Italy, compared to other large European markets, lacks a strategic plan to support the sector

The war on emissions has broken out and the goal set by the European Union for 2021 - a reduction in emissions of up to 95 grams of CO2 per km for new cars - is challenging, if not difficult. We know that carbon dioxide emissions are directly linked to the fuel consumed and the limit set implies consumption of 4.1 litres/100 km for petrol cars and 3.6 litres/100 km for diesel cars. This requirement has led to an interesting phenomenon: the proposal, made by suppliers, is to design hybrid and electric powertrains that would feature very low emissions in test cycles, even on the road. All with limited investments by OEMs because the development of these components is mainly supported by the suppliers themselves. This race towards a “greener tomorrow” has, to some extent, redesigned the role of component manufacturers and suppliers.

Constructive agreements

An example of this trend is an agreement between an engineering consultancy firm, Ricardo, and Chinese manufacturer Geely, owner of Volvo.

The Magma xEV project involves a combustion engine to drive an electric generator which, in turn, charges the battery and energises an electric motor. The unit promises excellent thermal efficiency, said to be 45% on the bench. We are looking at a unit with 4 valves per cylinder that operates as a Miller Cycle unit, characterized by the extended expansion phase compared to the compression phase. We can say that these are high compression engines, in which the intake valve closes very early in order to reduce the pumping losses during the intake itself.

A lower compression is therefore obtained, which decreases the temperature of the air-petrol mixture, minimizing the engine from “knocking” even with high geometric compression ratios. This allows the use of lean mixtures while the "long" expansion phase allows a lot of energy to be collected from the combustion gases.

Miller Cycle

Valeo is also in the game and formed an alliance with another supplier, the Dana Group, to create 48 Volt electrification systems. These are end-to-end groups designed for the hybridization of light commercial vehicles and to design electric units for 3 and 4-wheel passenger vehicles. Valeo will contribute with inverter and motor while Dana will provide its e-Gearbox transmission, dedicated to high-speed electric motors. The 48-volt solutions are interesting as the higher voltage compared to classic 12 V units is capable of managing appreciable power without the precautions required by 100-volt systems or above. No need to talk about high-end vehicles like e-Tron, Taycan and Model S: even a city vehicle like the Yaris Hybrid has parts with high voltage. The 48-volt engines can deliver a few dozen kW, enough for a small car and larger hybrid as well. The ideal use of the Magma xEV is in standard hybrid systems and range extenders.

A classic sheds its skin

Another solution, perhaps the closest to being made available commercially (OEM evaluations have already begun), is Mahle's MMHP (Mahle Modular Hybrid Powertrain), a "classic" supplier that has been able to reposition itself in a new technological scenario. The group produces modular turbocharged, 2- and 3-cylinder engines, which can contribute to traction if necessary by means of fixed ratio or 2/4-speed transmissions. The electric motor is always connected to the wheels while the ICE unit can be called into action when necessary.

The promised efficiency of the latter is very high despite its simplicity (2 valves per cylinder) thanks to the MJI system - Mahle Jet Ignition - which uses a pre-chamber with slots around the spark plug or in an integrated spark plug/injector assembly. The simple passive version already promises record breaking fuel consumption (207 grams/kWh) while the active version, with auxiliary injector in the pre-chamber, will drop to 195 grams/kWh thanks to very lean mixtures, with a ratio of about 2.

If the battery is charged, the vehicle will run in electric mode but if the voltage drops, the IC engine will recharge it, contributing to traction if maximum performance is desired.

Mahle estimates that the system applied to a compact SUV could reduce CO2 emissions, in the WLTP cycle, to about 18 grams/km. The weight of this modular hybrid engine is comparable to a 4-cylinder petrol unit with a 6-speed manual transmission. Mahle Powertrain draws on the multidisciplinary expertise of the Group, which will supply virtually all the components of the MMHP. It is no coincidence that the company produced a compact 48-volt battery with a promised life of 20,000 cycles. The capacity is 0.5 kWh but can be recharged at 20 kW peak, making it ideal for city stop-and-go use.

How to electrify an entire range

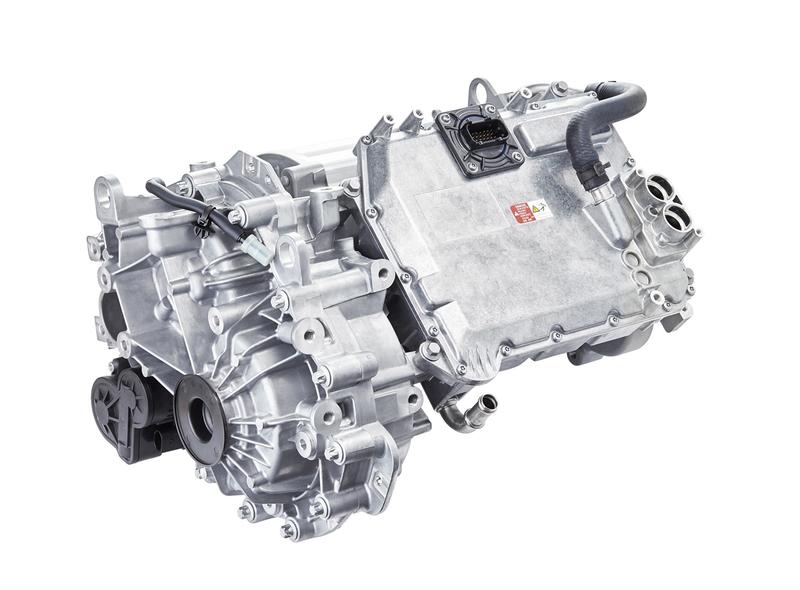

A new electric solution has the potential to spread widely as it will equip the electric versions of the Peugeot 208 and Opel Corsa as well as several Hyundai models.

The unit is an Axle Drive System mounted at the wheels and is supplied by Vitesco, a division of Continental specialized in powertrains and soon to be listed on the stock exchange. Here too we see the case of a classic supplier that has diversified from rubber components to electronics and sensors, ready to embrace the electric revolution. Production has already started at the Vitesco plant in Tianjin, China, while the e-CMP compact car platform has been developed in collaboration with Dongfeng.

This powertrain is comparable, in its most powerful version, to a 2-liter turbodiesel with 150 kW and 310 Nm torque, all in less than 80 kg. The unit integrates engine, transmission and inverter, thus simplifying and speeding up vehicle assembly operations.

The usefulness of these systems can clearly be seen, off-the-shelf solutions capable of lowering, with relative ease, the average CO2 emissions of an entire range of models with future stringent emission limits in view.

Jeep premières the E-axle

We report another important debut: the first Jeeps without drive shaft! The Plug-in hybrid versions of the well-known Renegade and Compass will in fact boast an E-axle at the rear, a solution seen during a visit to the FCA plant in Melfi during the ANFIA Public Assembly.

The rear wheel drive is entrusted to a rather powerful GKN unit (about 130 kW) controlled by an electronic signals; the space previously occupied by the shaft houses part of the battery, which has a slightly irregular shape. If GKN is a classic automotive supplier that is diversifying with electric systems, another company participates in the making of the new Jeep is not normally associated with mechanics. LG, a large Korean electronics group, will supply the battery (about 50 km of autonomy) and the high voltage starter-alternator capable of 33 kW and 53 Nm peak.

Electrification therefore offers space for new manufacturers, whether entire countries, such as China, or companies operating in different sectors. An example of this is the Italian Texa, active in equipment for diagnosis and A/C charging stations, which, during the last edition of Autopromotec, presented a very compact electric motor and its inverter. The axial flow design allows high power and torque (125 kW and 345 Nm) in a 12 cm thick motor with a diameter similar to that of a long play record. Such compact size and performance have also affected a supercar manufacturer, a prime example of the new frontier of electrification.

Italy, compared to other large European markets, lacks a strategic plan to support the sector

Ten million fewer vehicles produced and rising car prices from 2022

Industrial transition, components, infrastructures, electrification, hydrogen and alternative fuels take the stage